Things about Premier Aluminum Llc

Things about Premier Aluminum Llc

Blog Article

The 15-Second Trick For Premier Aluminum Llc

Table of ContentsAll About Premier Aluminum LlcAll About Premier Aluminum LlcThe Buzz on Premier Aluminum LlcNot known Details About Premier Aluminum Llc

(https://ameblo.jp/premieraluminum/entry-12878421249.html)Generally, a purchaser's main duty was to locate competent and responsive suppliers. In many cases, purchasers assumed that any type of vendor happy to contractually fulfill the acquisition requirement was qualified. Nevertheless, using inexpensive and unqualified distributors can create top quality problems, and threw away time and money in the future. To assist you through the procedure, here are some things to think about when selecting the right metal spreading supplier.

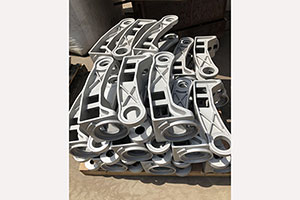

As an example, a firm that only utilizes the investment spreading procedure will try to sell you on why that procedure is best for your application. What if making use of the sand casting procedure is best for you and your needs? Instead, try to find a vendor that supplies a variety of casting processes so the very best choice for YOU is selected

If working with a solitary resource for all of your spreading needs is necessary to you, the provider requires to be diverse in its capacities. When integrated with various other integrated capacities, this can assist simplify and compress the supply base. When picking the ideal spreading distributor, careful consideration should be offered to top quality, solution, and price.

Premier Aluminum Llc Fundamentals Explained

Customers progressively pick casting suppliers that have machining capabilities. If the spreading vendor uncovers a concern during machining, the problem is solved faster with no disagreement over whose fault it is.

What do you learn the facts here now need from your spreading supplier? Are you looking for someone to simply supply a steel component to your doorstep or do you need extra?

Others will go beyond the letter of the PO to aid you save money and time. Do you have demands for both ferrous and non-ferrous alloys? Some shops are minimal or specialized. Make sure the provider can fulfill all your material or alloy demands to get rid of the requirement for several distributors.

How Premier Aluminum Llc can Save You Time, Stress, and Money.

Research study the provider's website. Speak to a sales associate or business associate. Ask a lot of concerns. See their facility. Obtain an understanding of what they can do for you and if you can see yourself constructing a solid, common partnership with them.

Aluminum is likewise lightweight and has excellent deterioration resistance, making it ideal for applications where weight and longevity are very important aspects. Additionally, aluminum casting is an economical approach of production, as it calls for less energy and resources than other techniques. Iron spreading, on the various other hand, includes putting liquified iron right into a mold to produce a desired shape.

Top Guidelines Of Premier Aluminum Llc

Iron spreading is also able to endure high temperatures, making it appropriate for use in applications such as engine parts and industrial machinery. Nevertheless, iron casting can be much more costly than aluminum spreading as a result of the greater price of resources and the energy needed to melt the iron. When deciding between light weight aluminum spreading and iron spreading, it is very important to take into consideration the details needs of the application.

In conclusion, both light weight aluminum casting and iron spreading have their very own special advantages and negative aspects. There are three sub-processes that drop under the classification of die casting: gravity pass away casting (or permanent mold and mildew spreading), low-pressure die casting and high-pressure die spreading. To get to the finished item, there are 3 primary alloys used as die casting material to pick from: zinc, light weight aluminum and magnesium. Report this page